Infinitely Recyclable

Aluminum is one of the most recycled—and recyclable—materials in use today. A recycled aluminum beverage can, car door or window frame is often recycled directly back into itself. And this process can happen virtually infinitely.

Circular Economy Solution

High value and infinitely recyclable aluminum is a material tailor-made for a more circular and sustainable economy.

- Recycling is a critical part of the modern aluminum business. Making recycled aluminum only takes around 5% of the energy needed to make new aluminum — reducing carbon emissions and saving money for businesses and end consumers.

- As a result, around 75% of all aluminum ever produced is still in use today, as shown by comprehensive industry data.

- In many industrial markets like automotive and building, recycling rates for aluminum exceed 90%.

- Industry recycling efforts in the U.S. save more than 90 million barrels of oil equivalent each year.

Recycling aluminum is good for the environment—and the economy. The U.S. recycles more aluminum today than ever before. And we're just getting started.

95%

Recycled aluminum saves 95% of the energy needed to make new aluminum.

$1B+

We could save more than $1 billion for the U.S economy each year by recycling all of our aluminum beverage cans.

80%+

Recycled aluminum makes up more than 80% of U.S. aluminum production.

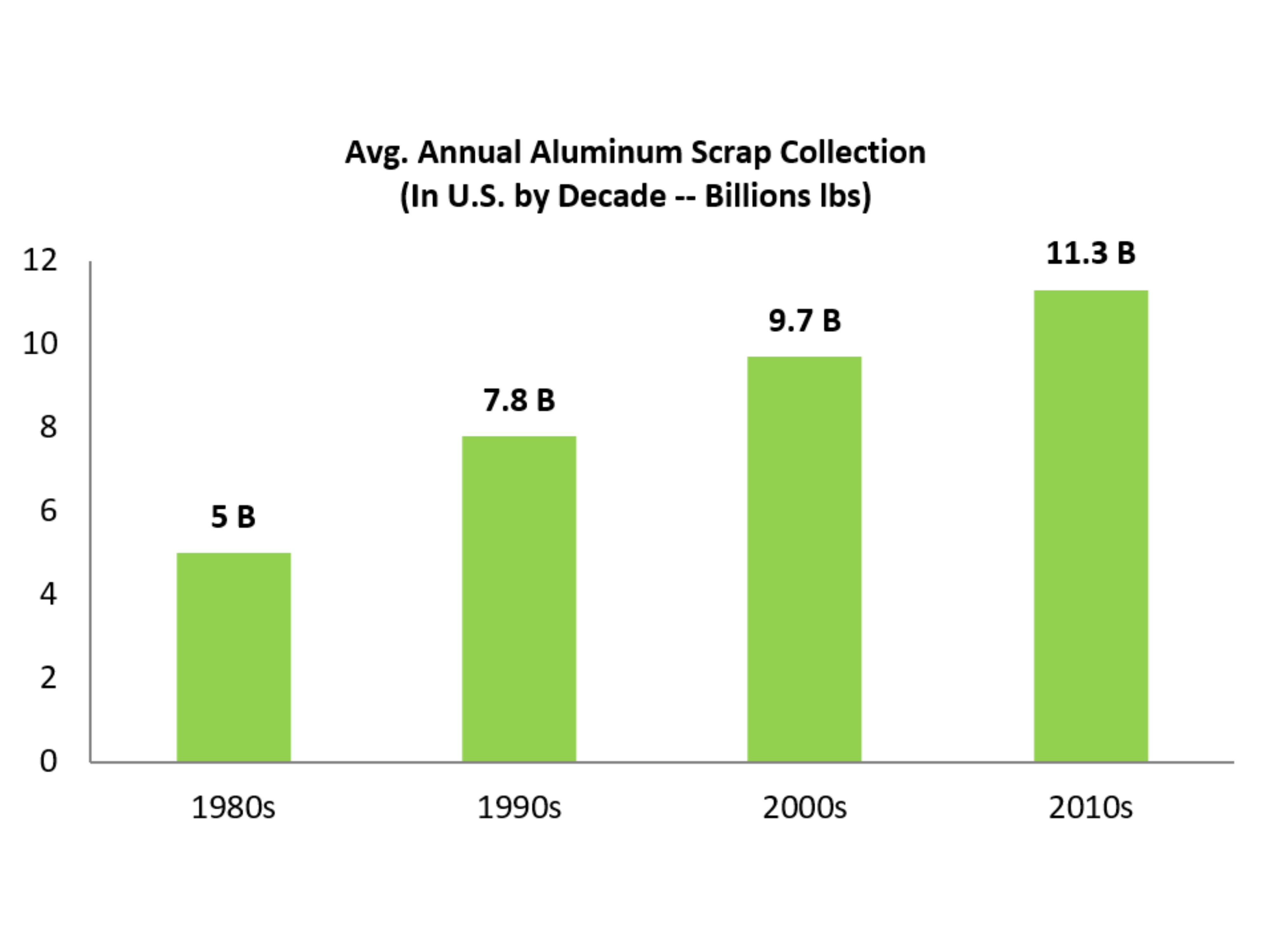

Recycling More Aluminum Than Ever

The U.S. collects more than twice the amount of aluminum today for recycling than it did in the 1980s. And while recycling rates in most industrial markets exceed 90%, we can do more — particularly when it comes to aluminum beverage cans.

While aluminum cans are recycled at far higher rates than glass or plastic, these rates have fallen below 50% in recent years. That means more than $800 million worth of aluminum ends up in a landfill — a tremendous loss to the economy and the environment. Learn more about how the Aluminum Association is leading the way to increase aluminum recycling nationwide.

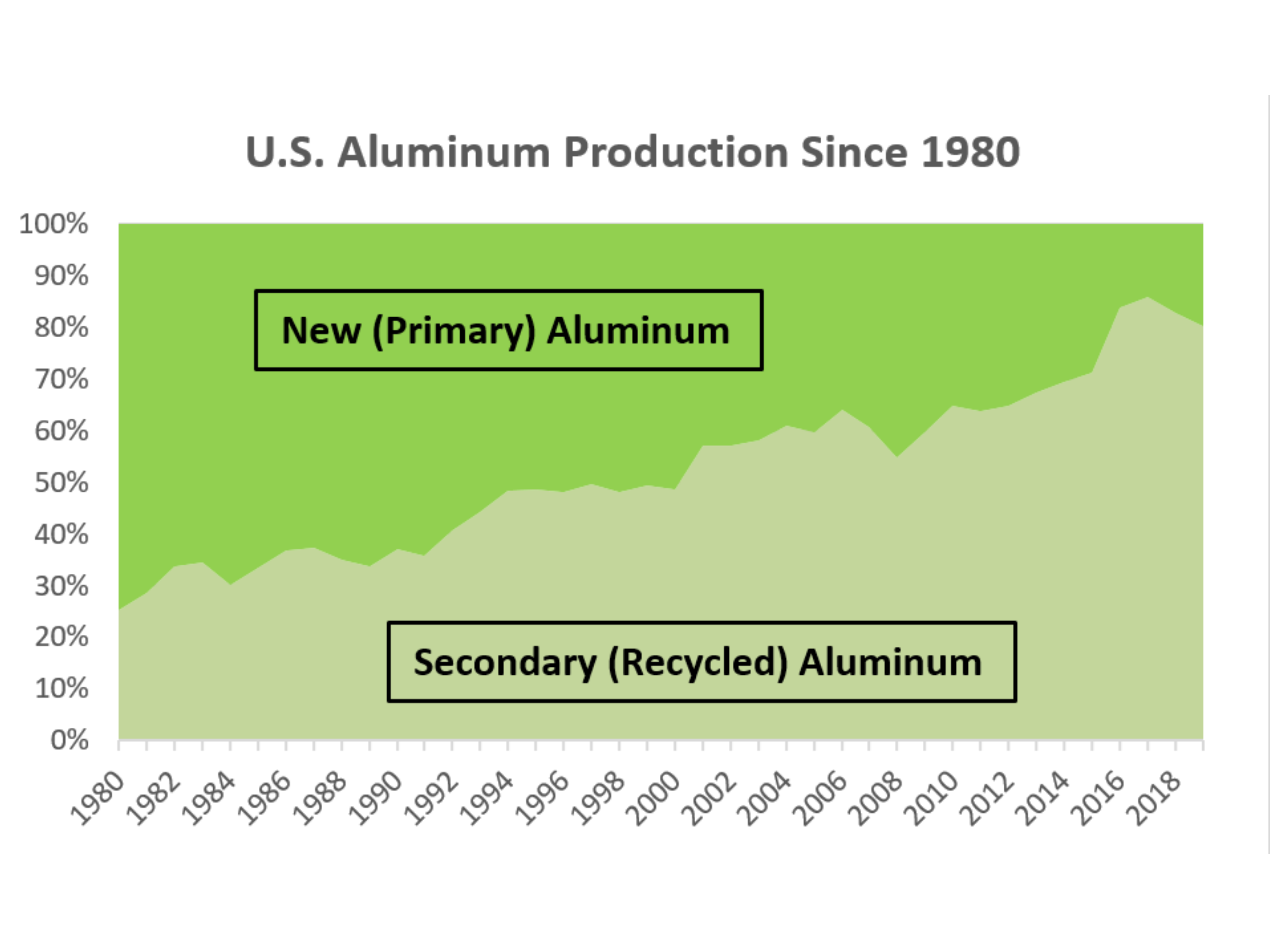

A Growing Secondary Production Market

Aluminum production in the U.S. is increasingly a story of scrap recovery and recycling. While primary aluminum production remains a vital part of the American aluminum supply chain, more than 80% of U.S. production today is in making recycled (or secondary) aluminum. This compares to 20% to 30% recycled production in the 1980s. All told, the U.S. produces more recycled aluminum than any single country other than China.

Increasing aluminum recycling translates to less energy used and a lower carbon impact. In the aluminum beverage can market, for example, each percentage increase in the end-of-life recycling rate reduces the carbon intensity of aluminum beverage can production by 1.02 kg CO2 equivalent per 1,000 cans. Increased recovery and recycling of aluminum is essential to continued industrywide decarbonization.

"Infinitely Recyclable" Explained

Aluminum, like all metals, is composed of atoms bonded together and formed in a crystal structure. This makes aluminum exceptionally easy to melt and reform into a solid state without changing its fundamental properties. This means that aluminum can be recycled repeatedly, back into use, with no theoretical limitation. In contrast, plastics are a polymer, a synthetic substance composed of very large molecules, which break down when mechanically recycled. Traditional recycling methods will degrade plastics to the point that they are ultimately no longer recyclable back into new plastic.

All materials lose some volume as part of the melting and recycling process, though in the case of metals the material itself is not degraded. In the case of aluminum, a small amount of metal is typically lost through mill operations or oxidation.

Despite this minimal melt loss, the remaining metal is fundamentally unchanged and can be recycled again and again … unlike plastics. A comprehensive industry mass flow analysis shows that nearly 75% of all aluminum ever produced is still in use today. And that metal is recycled over and over again.

What Others Say About Aluminum Recycling

A United Nations report notes:

- Metals are different from other materials in that they are inherently recyclable. This means that, in theory, they can be used over and over again, minimizing the need to mine and process virgin materials and thus saving substantial amount of energy and water while minimizing environmental degradation in the process.

A report by environmental consultancy Carbotech AG developed with the University of Applied Science North Western Switzerland described aluminum and other metals as a “permanent material”:

- A material is defined as permanent if its inherent properties do not change during use and through solid-liquid transformation, it can revert to its initial state. This is the case when the material consists of basic components, which are either chemical elements or robust chemical compounds, making repeated use and recycling possible without change of inherent material properties.

The "Father of Life Cycle Assessment" Weighs In

Jim Fava, widely regarded as “the father of modern life cycle assessment” noted in a report:

- Metals distinguish themselves because, as elements, the material stock is theoretically permanent: once metals are transferred from the natural resource stock and enter the economy, they can be recycled indefinitely, provided their purity is maintained and that systems are in place for their recovery.

- A great deal of the existing metal stock is still in use…Aluminum is continually recycled in closed loops from metal to beverage cans…All this means [is] that the time scale of the material stock of metals tends to be longer than for other materials…Typically, metals in the material stocks and product cycles can last beyond days to decades or even centuries.

The Aluminum Can Advantage

Aluminum beverage cans are the most sustainable beverage package on virtually every measure. Cans have a higher recycling rate and more recycled content than competing package types. They are lightweight, stackable and strong, allowing brands to package and transport more beverages using less material. And aluminum cans are far more valuable than glass or plastic, helping make municipal recycling programs financially viable and effectively subsidizing the recycling of less valuable materials in the bin.

Most of all, aluminum cans are recycled over and over again in a true "closed loop" recycling process. Glass and plastic are typically "down-cycled" into products like carpet fiber or landfill liner.

Learn more about the advantages of aluminum beverage cans by reading our annual Sustainability Key Performance Indicators report.