Aluminum Cans Leading the Way to Limit Carbon Impact

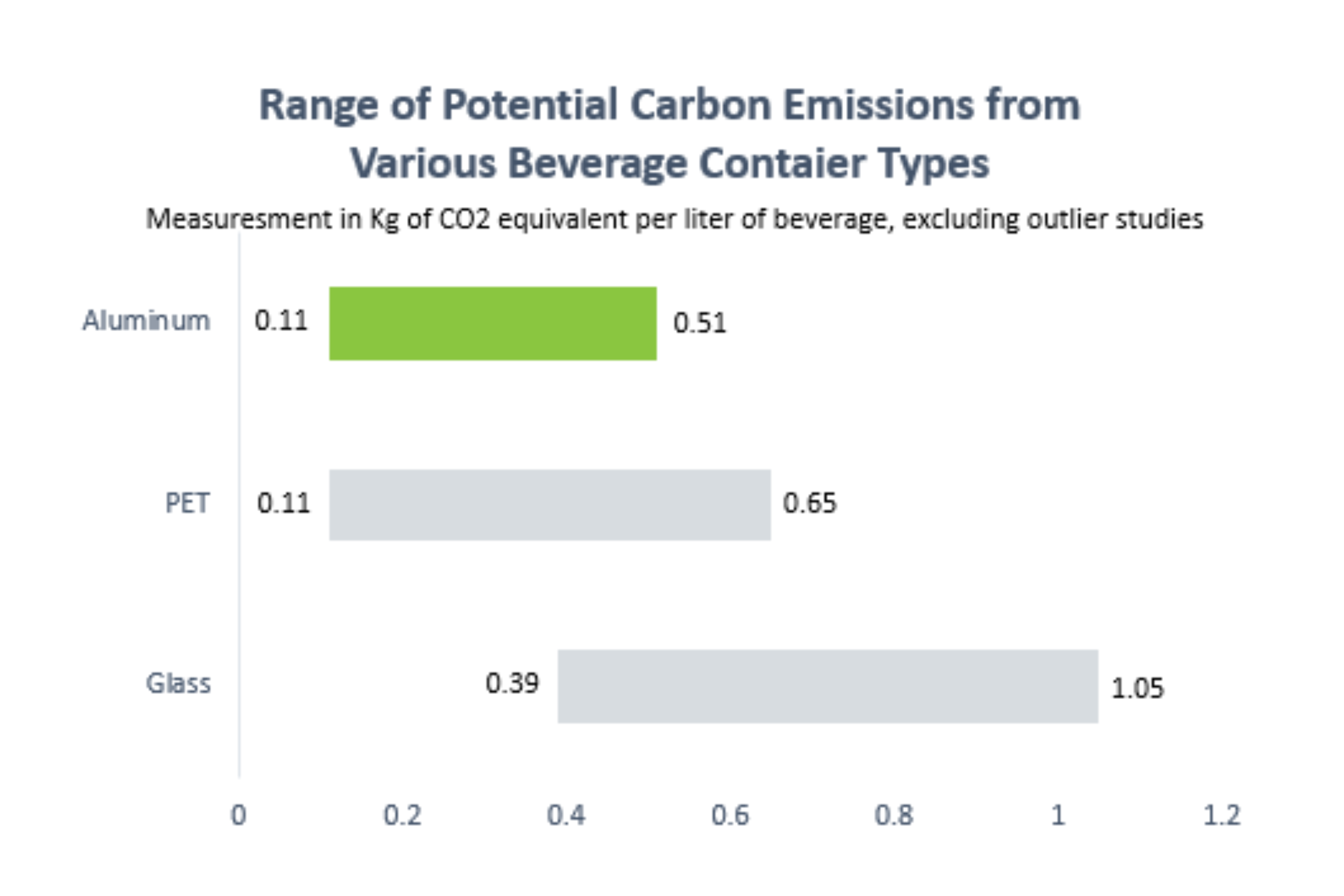

A third-party analysis of more than a dozen life cycle assessment studies found that aluminum cans used for carbonated beverages produce fewer carbon emissions than glass bottles and a similar level to plastic (PET) containers. Aluminum also offers a host of other environmental benefits from superior recyclability to greater circular performance.

Carbon Emissions Lower Than Glass, Comparable to PET

John Beath Environmental (JBE) reviewed more than a dozen life cycle assessment (LCA) studies comparing the global warming potential (GWP) of aluminum beverage cans, glass and plastic (PET) bottles used to package carbonated drinks. (GWP is measured in kilograms of carbon dioxide equivalents (kg CO2e).)

Excluding statistical outlier studies, the global warming potential (GWP) of aluminum beverage cans range from 0.11 – 0.51 kg CO2e per liter of beverage packaged; glass bottles from 0.39 – 1.05 kg CO2e; and PET/plastic bottles from 0.11 – 0.65 kg CO2e. While both aluminum and PET consistently outperform glass in terms of carbon emissions, the global warming potential of aluminum and PET containers are generally similar.

Challenges of Life Cycle Carbon Accounting

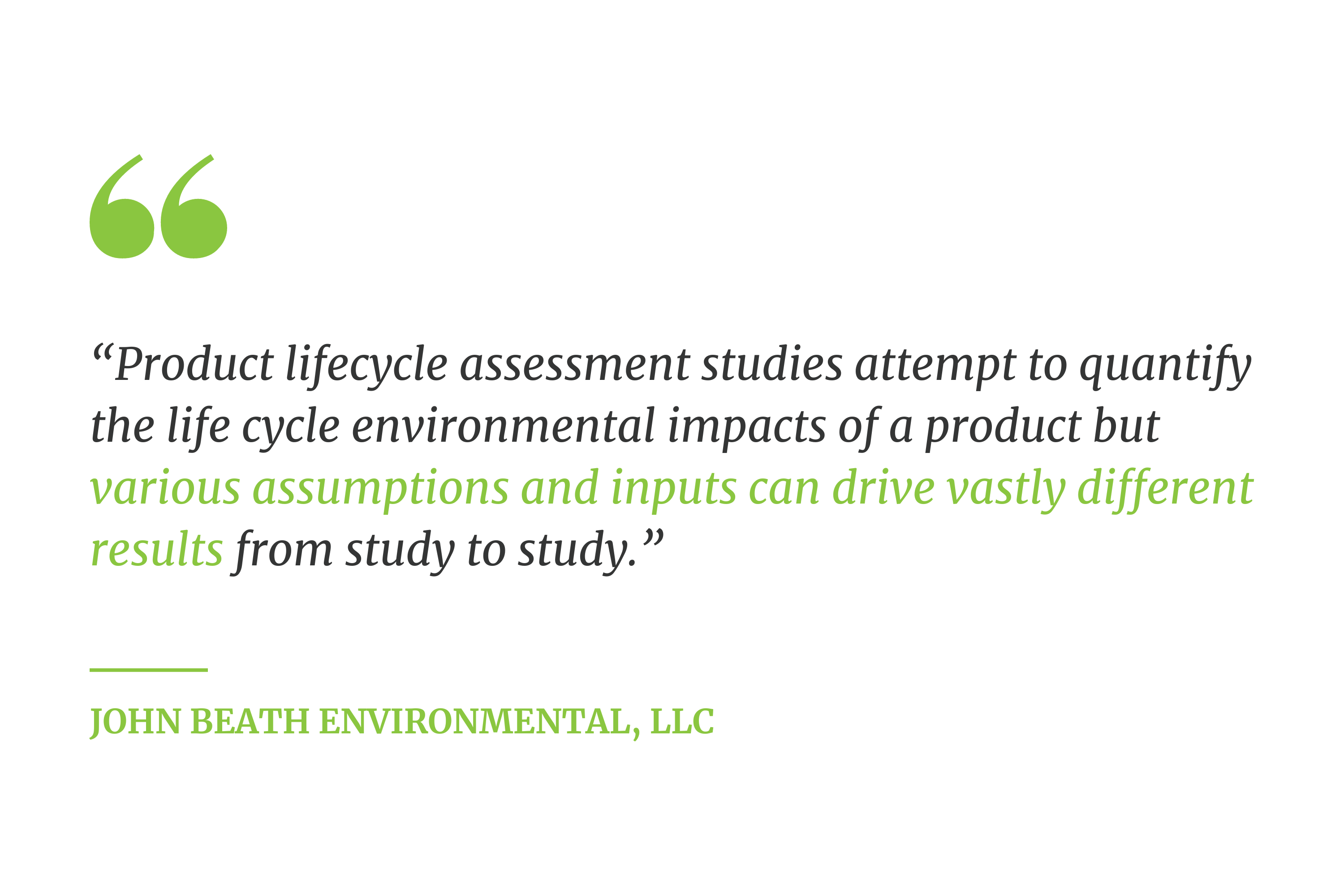

Product life cycle assessment (LCA) studies attempt to quantify the life cycle environmental impacts (including carbon impact) of a product from raw material extraction to recycling or disposal at end-of-life. Comparing the carbon impact of products is a complex and often imprecise process. Varying assumptions and inputs can drive vastly different conclusions from study to study.

Common challenges in developing studies comparing the carbon impact of beverage containers include:

- Product weight

- Container size

- Data quality

- Study boundary

- Beverage type

- Data transparency

- Methodological approach

Certain widely publicized studies comparing the carbon impact of beverage containers have significant flaws and do not comply with generally accepted International Organization for Standardization (ISO) rules for life cycle assessment reporting.

The Aluminum Can Advantage

Though not addressed in the JBE study, aluminum beverage cans have numerous environmental advantages over glass and plastic including superior recycling rates and far higher levels of average recycled content.

Globally, 75% of all the aluminum ever produced is still in productive use, while the vast majority of plastics have been dumped into landfills, oceans, parks and farmland posing health risks and damaging ecosystems.

Aluminum cans enjoy superior recycling rates to glass and plastic and more than 90% of the cans recycled in the United States are used to make new cans, unlike competing materials, which are often downcycled a single time – when they are recycled at all. The average aluminum beverage can manufactured in the United States contains 73% recycled content, compared to around 3% recycled content for the average PET bottle.

For more information, check out our latest key performance indicator report on the aluminum beverage can.

Ongoing Industry Improvement

The aluminum industry is working every day to further reduce its carbon footprint and other environmental impacts. Average carbon emissions for making aluminum in North America has declined by more than half over the past 30 years.

The use of aluminum enables lower carbon outcomes in markets like automotive, building and packaging. The aluminum industry continues to make progress through efficiency improvements; increased low carbon electricity use; efforts to increase end-of-life product recycling; and innovations like inert anode and other technologies that eliminate direct carbon emissions in the aluminum smelting process.

The Aluminum Association advocates strongly to grow aluminum beverage can recycling in the United States. The more we recycle, the more we can reduce the carbon impact of aluminum can production. The industry strongly supports federal and state infrastructure investment to grow aluminum recycling. Additionally, the association is advocating for new container deposit/recycling refund programs as the best way to bring back more aluminum beverage cans into the recycling system. Learn more at www.RecyclingRefundsWork.org.