NASA Takes Aluminum to the Final Frontier

Aluminum has played a crucial role in space exploration from the beginning, chosen for its lightweight strength and ability to withstand the stressors of space travel. Aluminum was used on Sputnik 1, extensively in the Apollo program, and even more recently in missions by SpaceX.

Aluminum in Space: A Timeline

Apollo 11’s mission to the moon relied heavily on aluminum. The Eagle lunar model was built almost completely of aluminum and used aluminum honeycomb shock absorbers. Aluminum performs particularly well in space thanks to properties that consistently outperform other materials in areas such as mechanical stability, dampening and thermal management.

In order to deliver hardware for the International Space Station, NASA needed to reduce the weight of the Space Shuttle’s external tank by 10% or 7,500 pounds. Rapid development of an aluminum-lithium alloy was instrumental in making that happen.

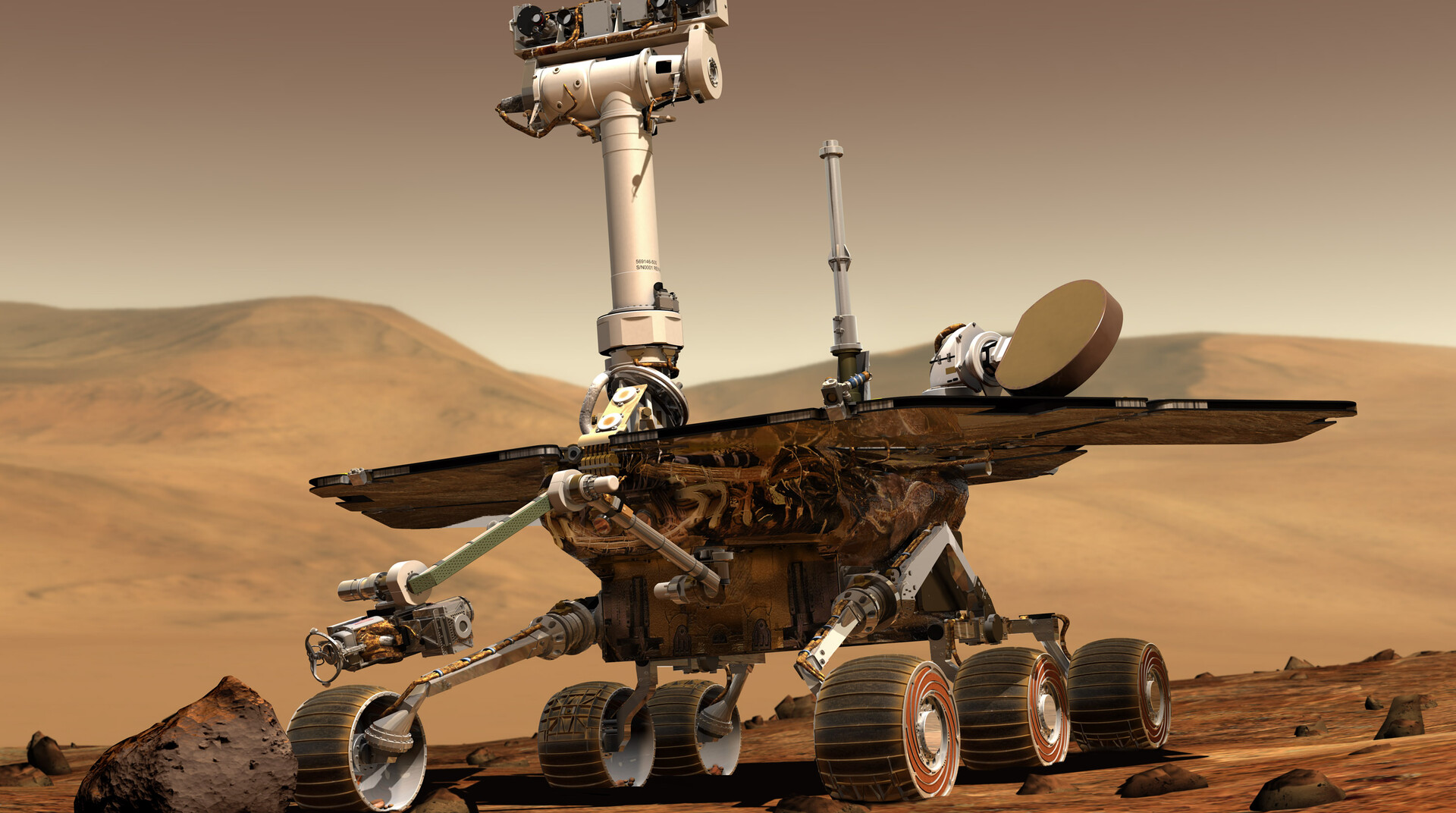

NASA launches the Mars Curiosity rover, a $2.5 billion robotic space exploration to search for evidence of past life on the surface of the red planet. Lightweight, durable and extraordinarily strong, space age aluminum alloys were the best choice to build the body and wheels of the nine-foot-long, 1,875-pound Curiosity rover robot. Like a car body, the rover’s aluminum shell is a strong outer layer that keeps the vehicle’s vital and sensitive electronics protected and temperature controlled.

NASA’s Orion Multi-Purpose Crew Vehicle launches. The Orion will serve as the next-generation space exploration vehicle. The primary structures of the Orion spacecraft are made from an aluminum-lithium alloy and will be covered by an advanced version of the thermal protection tiles used on the space shuttle.

Mars Perseverance was the first-ever aircraft to conduct a powered, controlled flight on another planet. This would not have been possible without aluminum, which contributed to its design with flight-grade aluminum and soft non-alloyed aluminum. These components allowed for the helicopter to be light-weight, survive freezing temperatures and last multiple landings.

Aluminum's Role in Aircraft & Aerospace

Even outside of space travel, aluminum powers modern flight. Aluminum alloys are the overwhelming choice for commercial planes and military cargo/transport aircraft. Entering mainstream use during and after World War II, it is no exaggeration to say that modern aviation and aerospace exploration would not have been possible without aluminum.