North American Aluminum Production Carbon Footprint Drops More than Half Since 1991

New Critical-Reviewed Life Cycle Assessment Shows 49% Carbon Reduction for Primary; 60% Drop for Recycled Aluminum

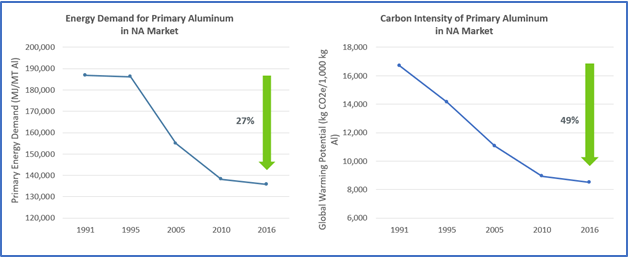

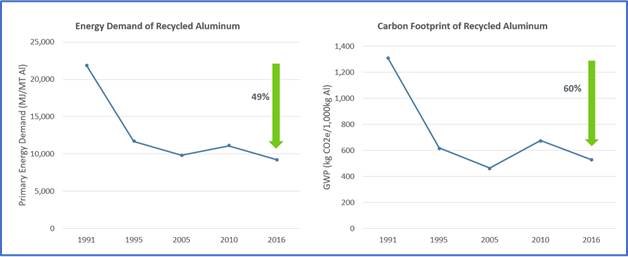

A brand-new, third-party critical-reviewed life cycle assessment (LCA) report shows that the energy and carbon impact of aluminum production in North America has dropped to its lowest point in history. Since 1991, the carbon footprint of primary aluminum production declined by 49% while the footprint of recycled aluminum production dropped by 60%. During the same time period, the energy needed to produce primary and recycled (or secondary) aluminum has dropped by 27 and 49%, respectively.

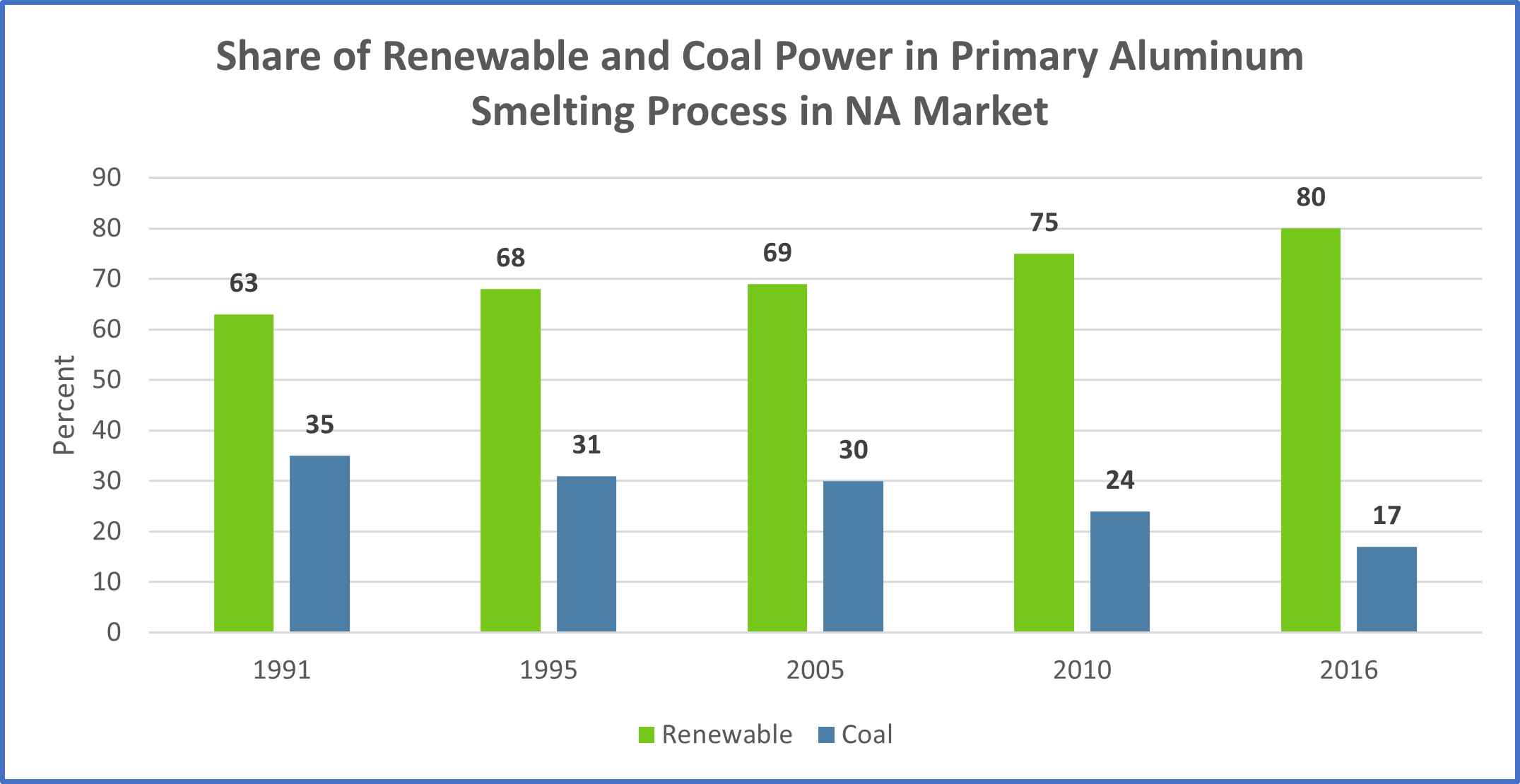

Between 2010 and 2016 alone, the carbon footprint of aluminum production (primary and secondary) declined between 5 and 21%. According to the report, aluminum produced in North America, which relies heavily on renewable hydropower, is among the cleanest in the world.

A graphic summary of the report’s key takeaways is available here.

The Environmental Footprint of Semi-Fabricated Aluminum Products in North America LCA report, developed in cooperation with sustainability consultancy Sphera, quantifies all material, energy use and environmental release impacts over the entire aluminum product life cycle, from raw material acquisition to end-of-life recycling and/or disposal. The study considers cradle-to-gate and cradle-to-grave life cycle stages. The report is based on aluminum and aluminum products manufactured in North America in 2016.

“The U.S. aluminum industry continues to innovate and find ways to produce this essential metal in as environmentally sustainable way as possible,” said Charles Johnson, president & CEO of the Aluminum Association. “And we’re nowhere close to done – every day, our members pursue new approaches to make this lightweight, durable and infinitely recyclable material using less energy and with lower emissions.”

According to the LCA report, raw material aluminum production – including both primary and recycled metal – represents the single largest element of the industry’s environmental impact for product manufacturing and has improved most substantially in the recent years. The impact of semi-fabricated aluminum production has also improved (Semi-fabricated aluminum is an "intermediate good" that has undergone significant processing but requires additional working before it is a finished product). Technological advancements including manufacturing process controls; efficiency improvements due to economies of scale; the phasing out of old smelting technologies; and the replacement of coal-fired for renewable electricity in smelting have all contributed to this positive trend.

“Beyond the upfront manufacturing impact, it’s also important to remember how much aluminum benefits products throughout their use phase,” Johnson said. “Aluminum makes buildings greener and last longer; vehicles go further using less energy; and packaging lighter, more efficient to ship and easier to recycle.”

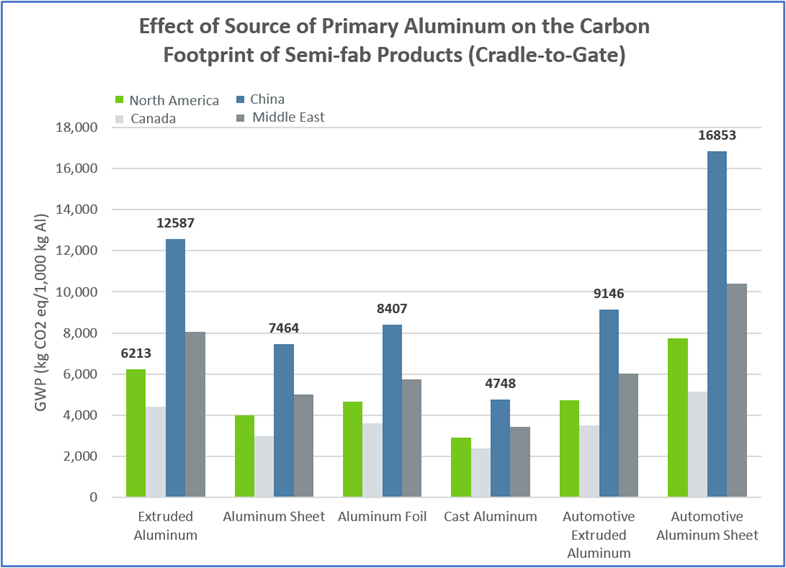

Regional variations in primary aluminum production also drive significant differences in the environmental footprint of various aluminum products. The LCA includes energy use and carbon footprint analysis of product types including extruded aluminum, aluminum sheet, aluminum foil, die cast aluminum, and aluminum sheet and extrusions for the automotive market. Making these products in regions like China or the Middle East – which rely largely on coal and natural-gas-based electricity – can be two to three times as carbon intensive as making similar products in North America, even assuming similar levels of recycled aluminum usage.

“We are proud of the fact that we make some of the cleanest aluminum in the world right here in North America,” added Johnson. “The message is clear – bolstering domestic aluminum production is good for U.S. manufacturing jobs and good for the climate.”

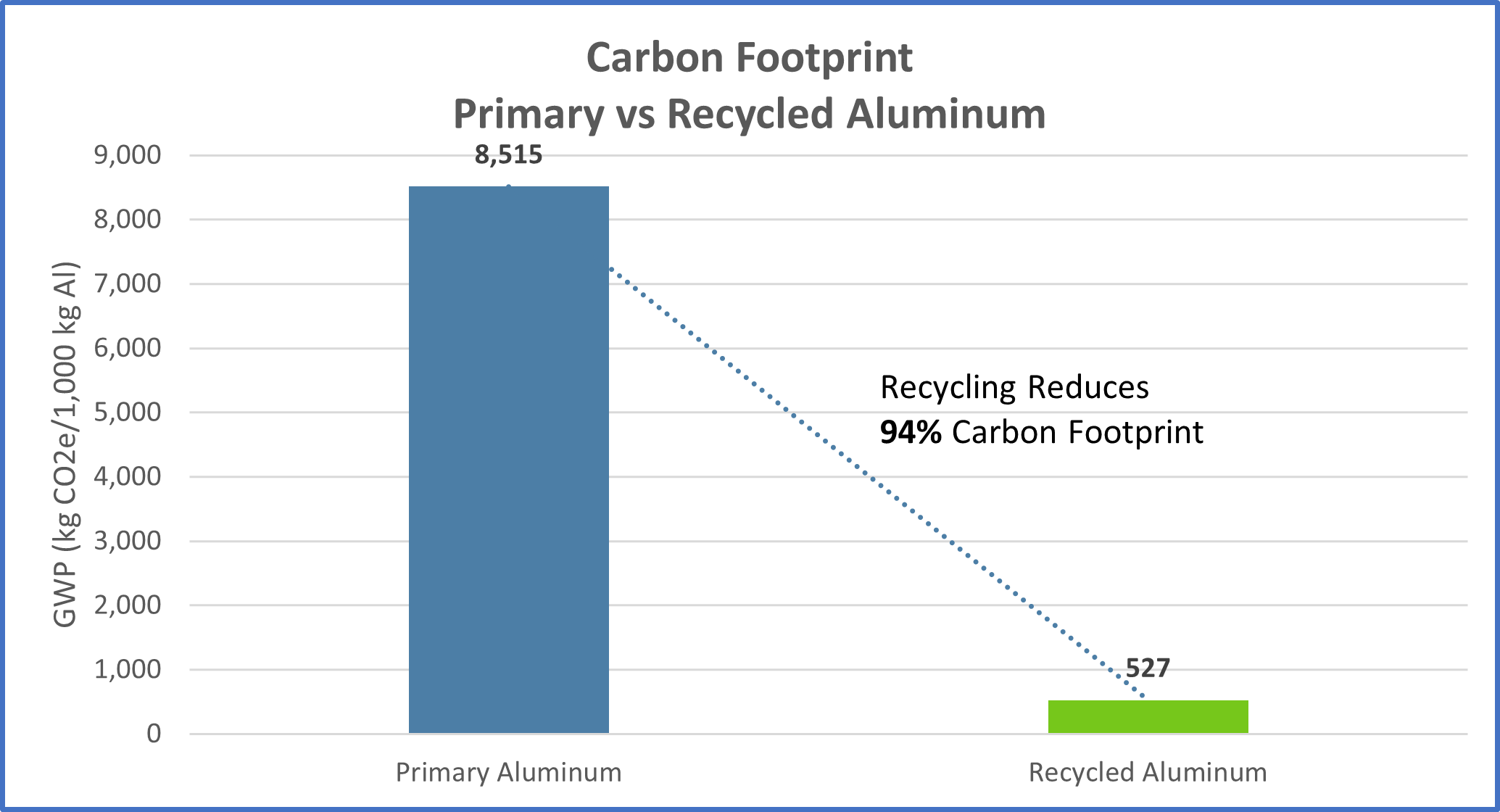

Increasing aluminum recycling also helps make the industry more sustainable. Making recycled aluminum is 94% less carbon intensive than making primary aluminum. Improving the end-of-life recycling rate for aluminum can also have a major impact. Increasing the aluminum recycling rate by 1% can reduce the overall product carbon footprint by 80 kg of CO2 equivalent per 1,000 kg of aluminum produced.

Unfortunately, more than a million tons of aluminum ends up in landfills every year in North America alone – a massive loss to the economy and the environment. The Aluminum Association is committed to increasing aluminum recycling rates and is working on multiple fronts to accomplish this goal, including advocating for new investment on recycling infrastructure and other policy changes to incentivize the increased collection and capture of used aluminum. Last year, the Aluminum Association joined the Can Manufacturers Institute endorsing an ambitious target to achieve a 70% recycling rate for aluminum cans in the United States by 2030.

In 2021, the Aluminum Association launched the Choose Aluminum campaign to highlight how the aluminum industry supports sustainable development in the U.S. and the rest of the world. Last spring, the association released the U.S. Aluminum Industry Sector Snapshot showing positive environmental trendlines for the U.S. industry on virtually every measure since the 1990s – a period when aluminum demand grew by 25%. And a product life cycle assessment report showed a 40% reduction in aluminum beverage can production carbon intensity since 1991. The ongoing campaign features videos with workers and aluminum leaders, a new sustainability website at ChooseAluminum.org and additional material highlighting the sustainable properties of the 100% recyclable, durable metal.

To review the full LCA report and to read additional life-cycle assessment on various aluminum products, visit www.aluminum.org/SustainabilityReports.

Matt Meenan

mmeenan@aluminum.org

703-358-2977